The PBCF (Propeller Boss Cap Fin) was developed in 1987 by Mitsui O.S.K Lines, along with West Japan Fluid Engineering Laboratory and manufactured by Nakashima Mitsuwa Propeller (formerly Midako Propeller).

Responsible for w/w sales of MOL PBCF is MOL Techno-Trade and Technava has been appointed agent in Greece since 1st Jan 2018.

MOL Techno-Trade renowned PBCF is a well-proven Fuel Saving technology, installed in more than 250GREEK vessels and more than 3.800 vessels worldwide (data from Jan 2023)

MOL Techno-Trade PBCF fundamental mechanism and effects have been repeatedly verified through numerous series of model tank tests and actual ship measurements from the first stage of the development.

Main benefits of MOL PBCF

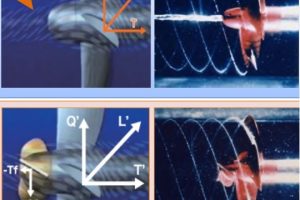

- Fuel Savings at levels of 3-5% and Return on Investment reaching half year

- Reduction of the Post Propeller Hub Vortex, thus increasing the Pressure (lower drag /higher thrust)

- Reduction of Propeller Torque (Power), due to Increased Force for Propeller Rotation

- Easy Installation , both for New-Buildings & Existing vessels (approx. half day in Drydock) – Also feasible for Afloat Installation

- No moving parts, no modification of the hull and no welding work is required.

- It can be installed on either fixed pitch or controllable pitch propellers.

- Optimized design and custom-made for each propeller.

- Installed in more than 250 GREEK vessels and more than 3.800 vessels worldwide (data from Jan 2023).

- New Design of PBCF for higher efficiency (Taller, Rounded, Curved) – abt 30% more Fuel Saving (as per CFD calculations, compared to conventional type of PBCF)

- Class Approval is not necessary.

- The major classification societies placed PBCF outside their classification rules.

- There is no need for vessels to be inspected upon docking

A detailed video demonstrating all above can be found in following link:

Basic Mechanism

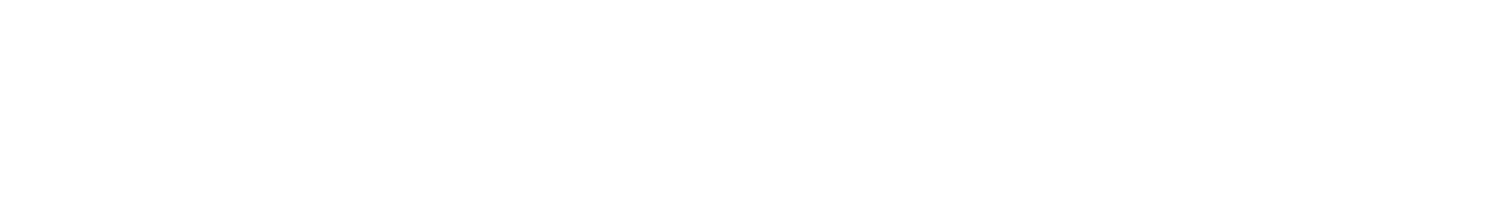

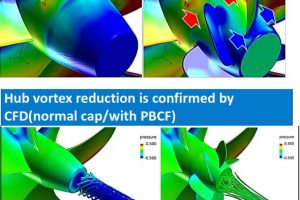

When a conventional boss cap is used, a strong vortex is generated which is called a “hub vortex”(*) and results in a loss of propeller efficiency.

When a PBCF device is installed on the propeller boss, the hub vortex will be eliminated as downward flows after the blade are blocked by the fins of PBCF.

As a result, the PBCF increases thrust and reduces shaft torque, improving propeller efficiency.

*What is hub vortex?

The difference in flow velocity between the upper and lower surface of the propeller blade results in a strong downward flow from the trailing edge of the blade.

The downward flow of each blade integrates into a strong hub vortex. As a result of the hub vortex, the propulsion energy of the propeller decreases

Without PBCF

The difference of the flow velocity hub vortex hub vortex between upper and lower surface of the propeller blade results in a strong down flow from the trailing edge of the blade.

The down flow of each blade combines and integrated into a strong hub vortex. Approximately 10% of the energy is scattered and is lost by this hub vortex and so on.

With PBCF

The strong down flow from the propeller blade trailing edge will be rectified by the PBCF fins to reduce the rotatable component, so that the fins will produce the force reducing the propeller shaft torque by 3% and more. In addition, thrust will be increased by over 1%.

Effect

The PBCF achieves an energy saving of up to 5% at the same speed, or at the same horsepower, the vessel’s speed increases by about 2% by fitting the PBCF.

Other merits

- Reduction of torque-rich conditions

- Reduction of stern vibration and underwater noise

- Elimination of rudder erosion

Please contact Technava’s Project Department for a detailed presentation at your premises.